How to Distinguish Between a Batch Oven and Other Industrial Ovens

The depth, height, and width of industrial ovens may vary as they appear in a plethora of combinations. There are a few ovens that come with tongue and groove panels and are easily available in the market. On the contrary, there are a few ovens that possess advanced features.

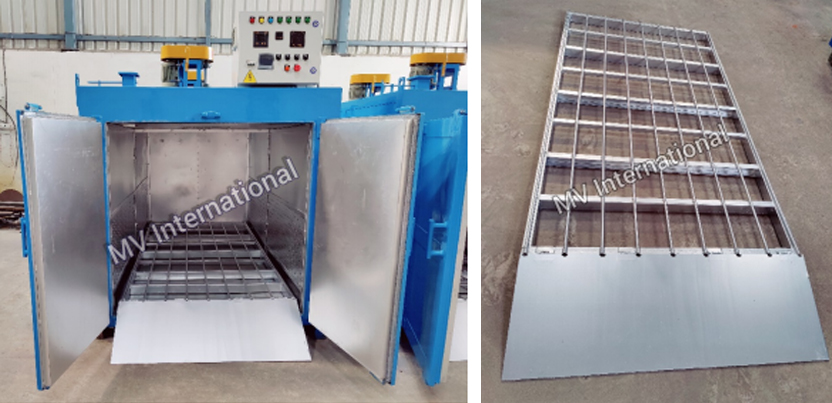

Few of the modern ovens appear with insulation in the walls and their inner space holds steel-frame structures.

How efficient is a Batch Oven?

The method of construction provides for a high quality Batch Oven that proves sturdy and energy-efficient. These ovens are capable of serving various industrial applications for several years. They are even known for undisputed quality.

Depending on your application, you will need to engineer the batch equipment. Other important factors that affect the performance of the oven include its capacity to achieve 1,000oF, heating process and part size. Standard batch ovens are usually used for acquiring temperature of up to 500oF and they come with multiple features.

Most of the industrial heating requirements can be performed by a pre-tested and pre-engineered batch unit. Alongside a lower running cost, the oven even offers the advantage of a lower processing time. The latest airflow technology followed by a Batch Oven Manufacturer helps it deliver high quality performance. All of your industrial production needs can be fulfilled easily as the oven operates 24x7.